Educate guests about plastic recycling and handout beautiful functional products.

The Events Starterkit comes with a six cavity aluminium carabiner mould so you can produce plenty of products for guests. We can also add a custom engraving of your project’s logo into the mould so it appears on every product.

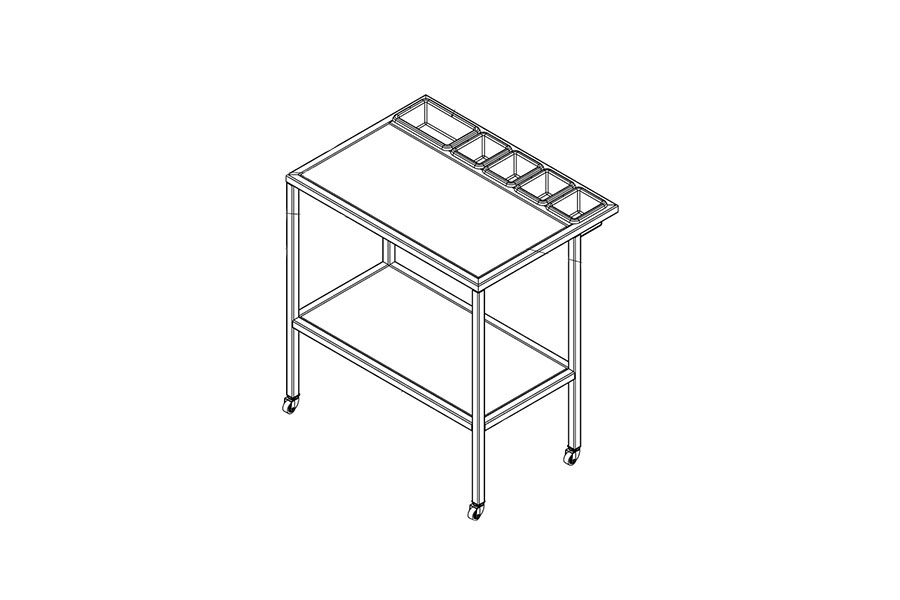

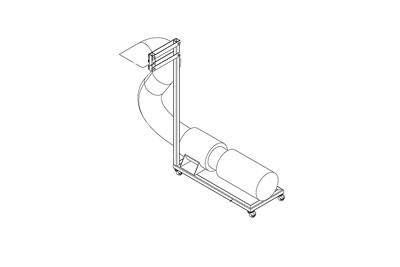

The shredder machine turns plastic waste into small flakes - your new raw material for making products. The shredder can process between 10 and 27 kg per hour depending on the type and size of material.

We provide high-quality thoroughly tested machines made to the latest Precious Plastic specifications.

Inject shredded plastic into a mould to create small functional products you can handout to guests during a workshop or an event. It’s a quick process (around 8-10 mins per round) and perfect for explaining the basics of plastic recycling.

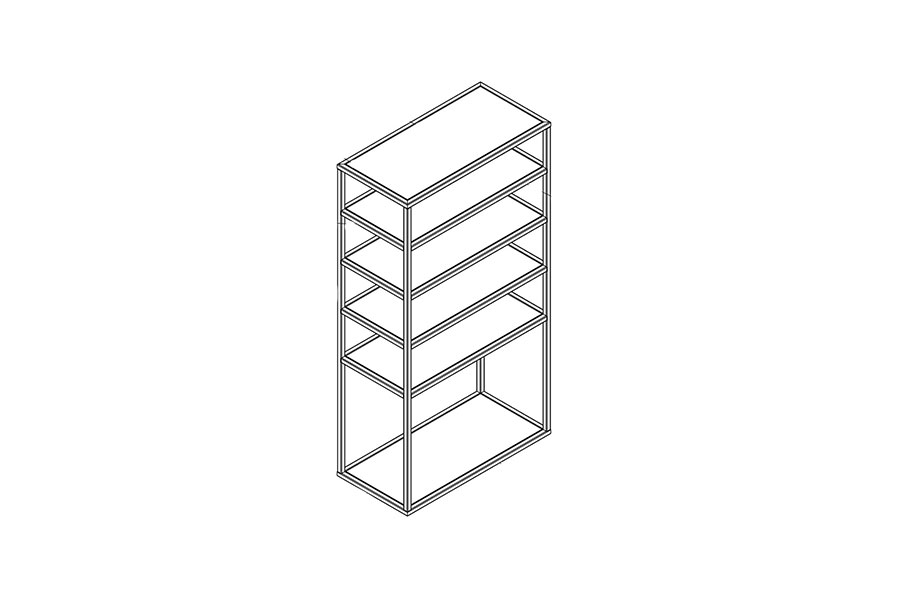

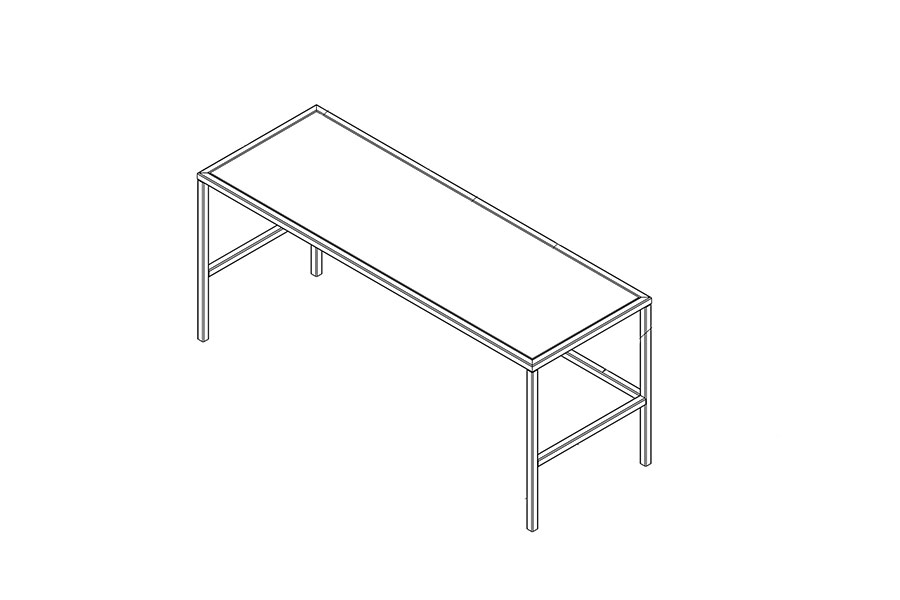

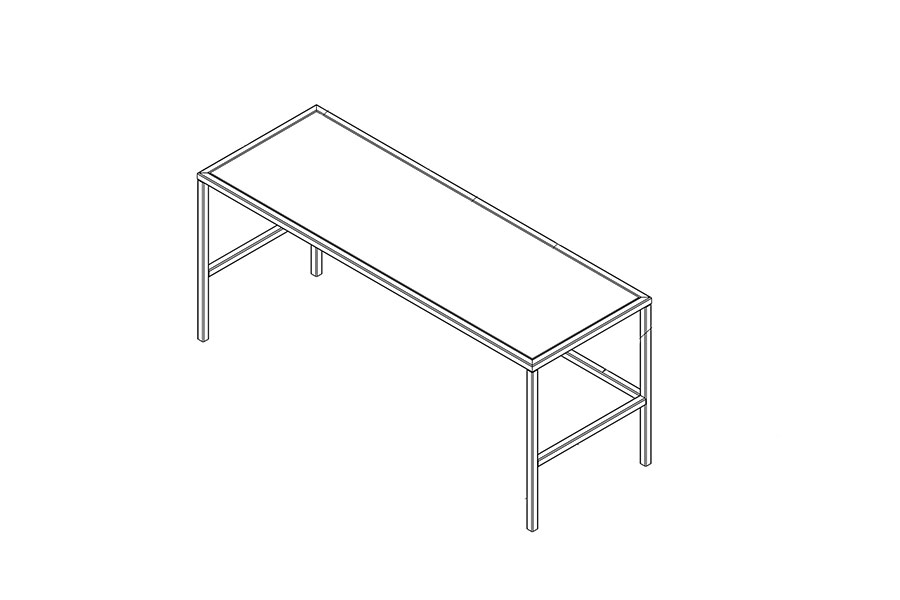

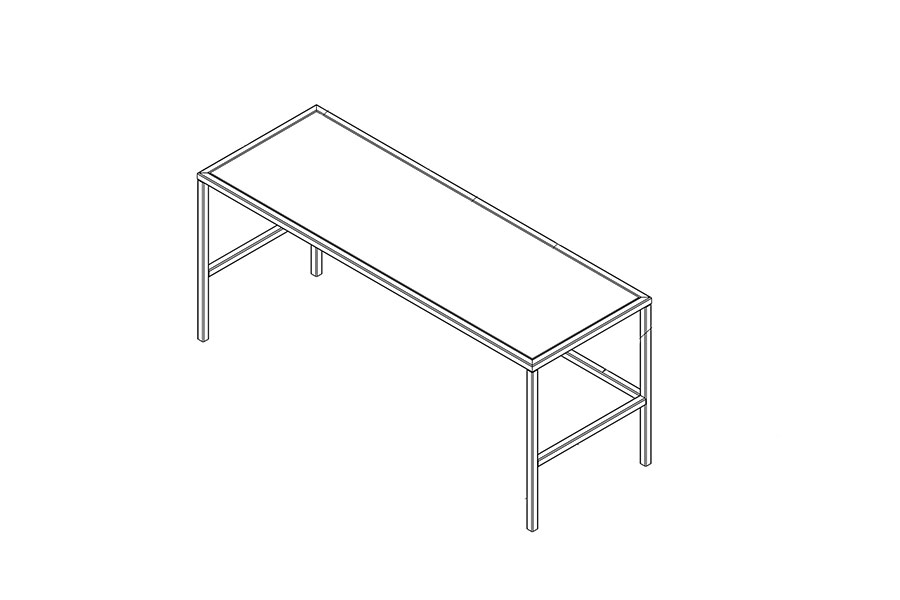

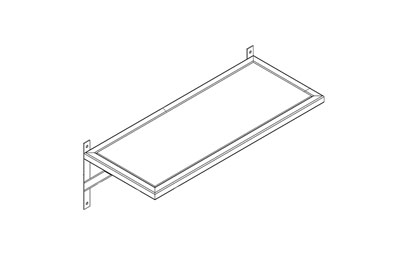

We offer the whole package - accessory furniture to run events, a ventilation caddy, recycling posters, badges, and everything else you need to set up your project to run recycling events.

Get started the right way with one-on-one support, counselling and guidance straight from the Precious Plastic team. Taking you from zero to hero, the Precious Plastic way.

The Events Starterkit covers a digital session on machine setup, maintenance, and safety, plus we also offer upgrades for additional support.

With the Events Starterkit you can tap into the Precious Plastic Universe. An active ecosystem of resources, platforms, tools and people collaborating and recycling plastic worldwide.

The Events Starterkit provides you with everything you need to get started producing recycled plastic bricks.

But why not go pro? You can add upgrades to take your project to the next level. Have the Precious Plastic team setup your workspace onsite, 30hrs ongoing digital support to help you over time or a promotional video in Precious Plastic style.

The Precious Plastic team has set up workspaces in Kenya, the Maldives, Chile, and Bangladesh - your country could be next.

Setting up new projects and working with Precious Plastic workspaces around the world has taught us a lot about small scale plastic recycling such as what plastic to collect, which machines are best suited to which scenarios, and how to design products from recycled plastic. This experience applied to your project can help make it a success.

To run a workspace producing bricks, you need to set up a small team (at least 2-3 people) to carry out all the necessary tasks.

We advise you to find a space at least 30 sqm to operate comfortably and safely. You might want a bigger space if you plan for more guests.

You need to find a source of plastic waste to feed the recycling process. Clean plastic (#2 HDPE or #5 PP type) works best for injecting products.