FabLab is engaged on various types of the projects and research, from local community, national or international projects to commercial, private sector innovation, research and development for products and services. Please check out list of our exemplary projects.

Cobot TLF in Sarajevo will connect with current and future learning factories of EIT Manufacture network....

STEM workshop is designed to teach young people about 3D technologies in a fun way, where through the creation of prototype products based on their ideas.

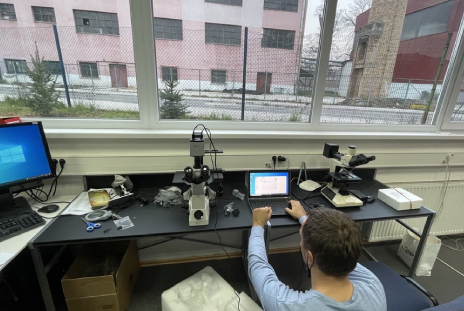

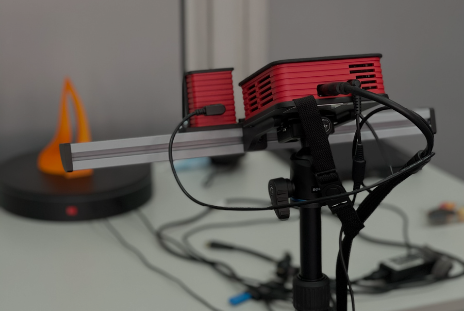

Establishment of an optics laboratory.

The Project will establish a maker movement in BiH and foster strentenigh in Visegrad region. Thee new partnership among FabLabs from Czech Republic, Hungary, Poland and Slovakia and BiH will support sharing know-how, ideas and good practices. Partnering with other makers and businesses, FabLabs will, through the maker movement, encourage science popularization, even in hard-to-reach communities.

Aim of the projects is to determine capacity, survey current situation, display current technology solutions and create feasibility study for Sarajevo museums and institutes of culture..

CEI funded project with aim to develop and strengthen the competences related to 3D technology in medicine and health care. Participants: University of Zenica, University of Pavia, Politecnico of Torino and FabLab BiH

FabLab organized a training in the basics of 3D printing and AM for Faculty of Pharmacy staff. Attendees gained practical knowledge of 3D printing and its application in the pharmaceutical industry. 3D drug printing may become the biggest technological leap in the pharmaceutical segment, and according to the optimistic forecasts, it will soon be available in BiH as well.

Faculty of Mechanical Engineering Sarajevo, in cooperation with FabLab, organized an internship for 10 students of III and IV year of study. During the internship, students worked on the various creative 3D printing projects: - Ultrasonic toothbrush cleaner - Hydrodynamic transformer - Special purpose clamping tool - Lightweight frame for drones.

'3D printing in pharmacy' was established based on cooperation with the Faculty of Pharmacy in Sarajevo, the Faculty of Pharmacy in Belgrade and Hemofarm company. The aim of the project was to present new interdislinary field, its applications, but also the challenges through a two-day training and confrence.

To make as many women become interested and involved in the field of additive production, a

branch of the global network 'Women in 3D

Printing' has been established in Sarajevo.

We organize regular events with guest lecturers and leading experts from around the world.

You can find out information about new events via our website or social networks.

The project ‘Improving STEM Education with 3D Scanning’ is supported by the Federal Ministry of Development, Entrepreneurship and Crafts. The aim of the project is to strengthen the capacity of FabLab through the procurement of 3D scanners with the aim of establishing inclusive STEM education and training of young people to work on additive technologies, including project equipment.

Fisheries represent a very important source of food for billions and livelihoods for millions of people worldwide. Technological innovations together with IPR best practices present great opportunities in promoting healthy fish populations, feeding billions of people, and at the same time adapting to the impacts of climate changes. Patented.

The spectrometer is a device that resolves the input light on its constituent colors and quantifies them. It is a very useful instrument in science laboratories and an excellent educational tool for chemistry, biology, or physics of light. FabLab Sarajevo has developed a fiber-coupled spectrometer and a cuvette holder that make the conduction of experiments easy and repeatable.

We have assisted in fabrication, design changes and final design of the first portable pulse oximeter produced in Bosnia. Portable pulse oximeter is a small, rapid, noninvasive, and lightweight device used to monitor the amount of oxygen carried in the body. Product is patent pending and further detail will be available once product is patented.

We have assisted in fabrication, design changes and final design of the custom orthopedic active medical instrument. Product is patent pending and further detail will be available once product is patented.

The high cost, technical difficulty of making product prototypes, and lack of skills or knowledge, have long been roadblocks for SMEs and startups seeking to innovate, bring new ideas to market or to compete with others. FabLab recognized this problem and has put digital fabrication within financial reach of SMEs and startups, or even for full-time jobers trying to explore an alternative career, significantly simplifying the process of prototype or product development.